The Role of IoT in Revolutionizing Manufacturing Processes

The rapid evolution of technology has brought forth several advancements that have revolutionized various industries, and the manufacturing sector is no exception. One such advancement is the Internet of Things (IoT), a network of interconnected devices that communicate and exchange data. In recent years, IoT has been playing a crucial role in transforming manufacturing processes, leading to improved efficiency, productivity, and safety.

One of the key benefits that IoT brings to manufacturing is predictive maintenance. Traditionally, maintenance has been a reactive process, with machinery being fixed only after a breakdown. However, IoT enables real-time monitoring of equipment, allowing manufacturers to identify and address potential issues before they cause any disruption. By analyzing data collected from sensors attached to machinery, manufacturers can predict when maintenance is required and schedule it accordingly, minimizing downtime and saving costs.

Furthermore, IoT devices provide manufacturers with valuable insights into their operations. By capturing and analyzing data, manufacturers can gain a deep understanding of their production processes, identify areas for optimization, and make informed decisions to increase efficiency. For example, by monitoring energy consumption data, manufacturers can identify areas of wastage and implement energy-saving measures, reducing costs and improving sustainability.

Another area where IoT is revolutionizing manufacturing processes is supply chain management. With IoT devices, manufacturers can track the movement of goods in real-time, ensuring timely delivery and minimizing the risk of loss or damage. By leveraging IoT technology, manufacturers can also create a more transparent and efficient supply chain. For instance, by implementing RFID or GPS tracking, manufacturers can monitor inventory levels, identify bottlenecks, and streamline logistics, reducing lead times and improving customer satisfaction.

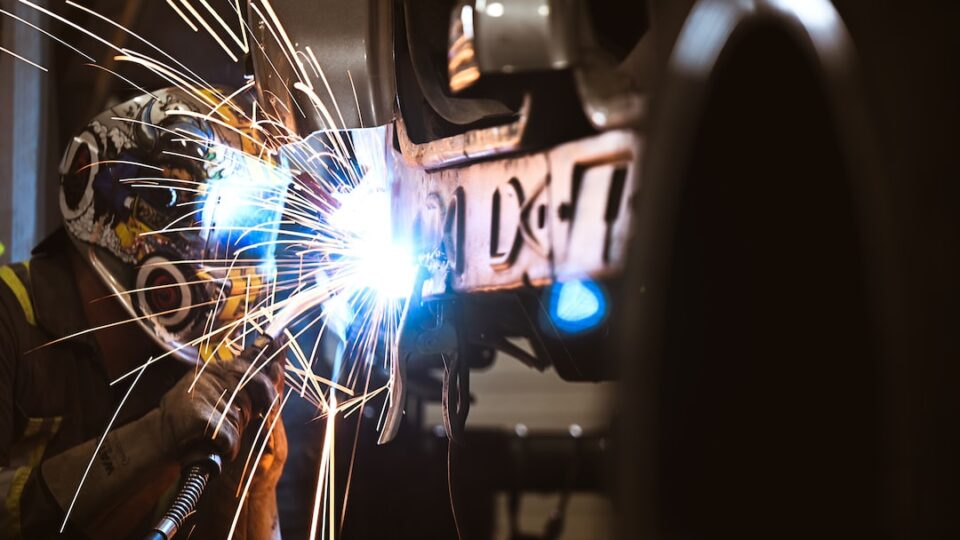

The integration of IoT into manufacturing processes also enables manufacturers to embrace automation and robotics. IoT devices can communicate with machines and coordinate their actions, facilitating a seamless flow of operations. This integration allows manufacturers to achieve higher precision, speed, and consistency in their production processes. Additionally, robotics, when combined with IoT, can enhance safety in manufacturing environments by automating hazardous tasks traditionally performed by humans. This not only reduces the risk of accidents but also allows human workers to focus on more analytical and complex tasks.

Moreover, IoT is playing a pivotal role in achieving a connected and smart factory. By connecting every element of the manufacturing floor, including machinery, personnel, and inventory, manufacturers can achieve real-time visibility and control over their operations. IoT devices can collect data from various sources and provide manufacturers with actionable insights. For instance, manufacturers can monitor the performance of individual machines, identify patterns, and make data-driven decisions to optimize production schedules and increase output.

In conclusion, IoT is undeniably revolutionizing manufacturing processes by bringing numerous benefits. From predictive maintenance to improved supply chain management, IoT has the potential to enhance efficiency, productivity, and safety in the manufacturing sector. By leveraging the power of IoT devices, manufacturers can transform their operations, create smarter and connected factories, and stay competitive in the ever-evolving industry. As technology continues to advance, embracing IoT in manufacturing will undoubtedly become a necessity rather than an option.